News Story

MEI2 seed grant receives BETO SBIR Funding

The Bioenergy Technologies Office (BETO) selected 13 small businesses working to accelerate bioenergy R&D. The companies, located across 10 states, have been selected to receive up to $206,500 each for this Phase I SBIR award. Of the 13 BETO awards, six are first-time awardees, four are located in Historically Underutilized Business (HUB) zones, two are in socially and economically disadvantaged areas, and one is a woman-owned business.

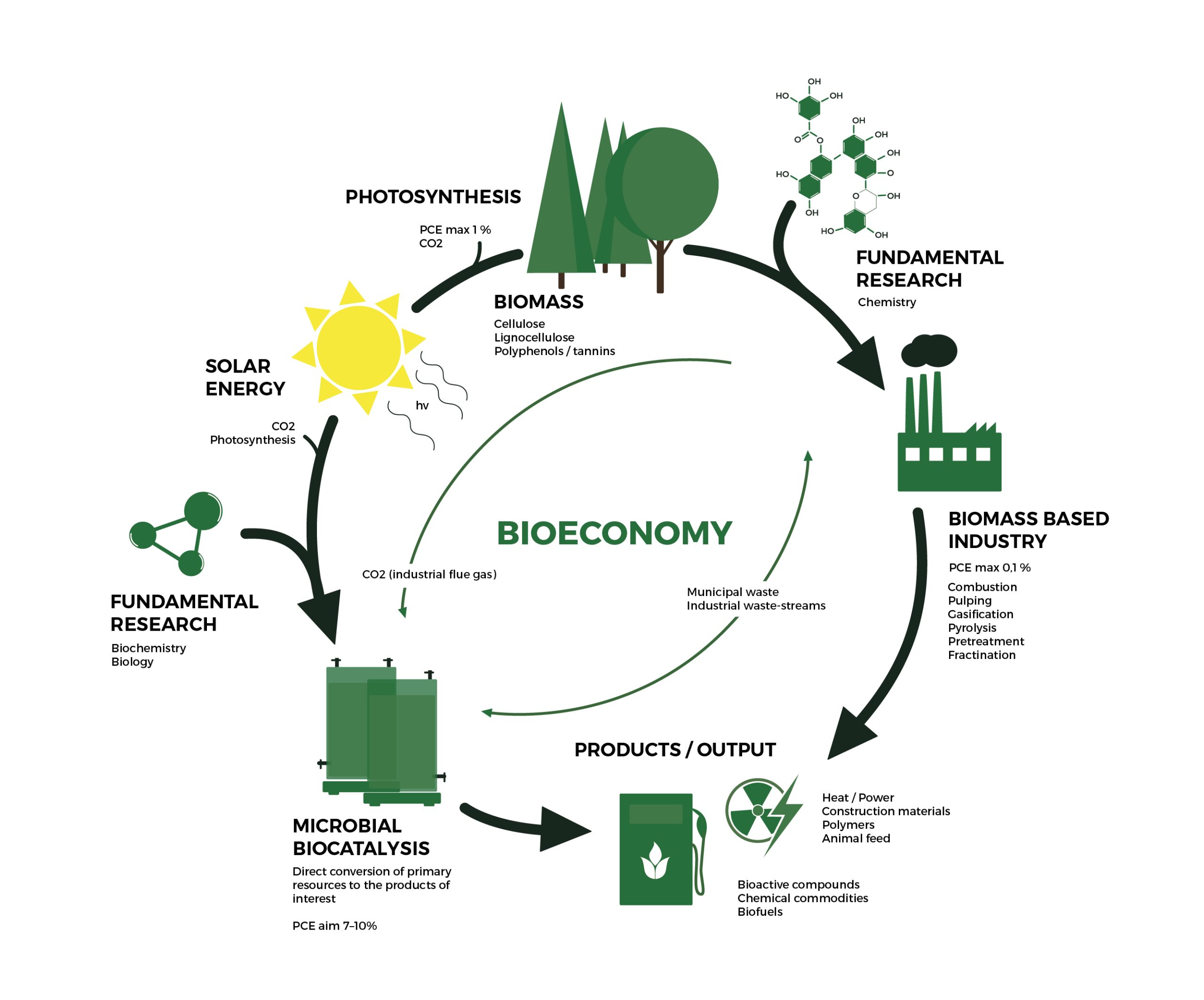

BETO is focused on research, development, and deployment to produce “drop-in” biofuels from renewable biomass and waste resources that are compatible with existing fueling infrastructure and difficult-to-electrify modes of transportation including aviation, maritime, rail, and medium-to-heavy duty off-road vehicles. Rather than developing new equipment, the intent of this topic is to test commercially available equipment, with minor or major modifications, to demonstrate preprocessing of biomass and waste feedstocks.

Atlantic Biomass Conversions, Inc. (Frederick, MD) will be funded for its project: Low-Cost Production of Sustainable Aviation Fuels (SAF) from Perennial Feedstocks using Simultaneous Ball Milling and Enzyme Hydrolysis.

Work on this project will be performed by Atlantic Biomass with their STTR Institutional Partner, The Ohio State University Department of Food, Agricultural and Biological Engineering located in Wooster Ohio. Dr. Fred Michel of OSU has been working with Atlantic Biomass on the development of this system which began in an earlier Maryland Energy Innovation Institute (MEI2) Seed Grant program. Dr. Kim Daehwan of the Biology Department of Hood College in Frederick, Maryland will be performing biomass structural analysis for the project. In addition, growers from the Association of Warm Season Grass Producers will provide samples of switchgrass and miscanthus from their commercial crops for testing and analysis.

Bob Kozak, President and Founder of Atlantic Biomass, explained that purpose-grown herbaceous energy crops have the potential to provide 535 million dry tons of new biomass to the U.S. bioeconomy according to the latest DOE Billion Ton Study. These perennial grass energy crops, however, as DOE references in that report, need SAF-based processing breakthroughs to make them commercially viable.

“We think the innovations that our team will make with this important STTR grant will help our simultaneous ball milling/enzyme hydrolysis process to achieve these DOE perennial grass goals,” said Kozak.

This grant was awarded by US DOE under the Alternative Uses of Commercial Equipment (ACE) topic. Instead of developing new equipment from scratch, the intent of ACE is to use the expertise of cutting edge small companies to modify and improve available equipment, to improve the processing of biomass and waste feedstocks.

The Atlantic Biomass optimized simultaneous ball milling/enzymatic hydrolysis process will make the production of fermentable sugars from biomass more cost efficient by eliminating pretreatment steps of current technologies. These biomass sugars will then be fermented into ethanol using the Atlantic Biomass combined fermentation and distillation system developed with MEI2 Seed Grant funding. Bacteria that convert glucose and other biomass sugars will be utilized. This increases ethanol production by about 20% over conventional glucose-based systems. The ethanol would then be used as feedstock for sustainable aviation fuel or other chemical products.

“Overall, STTR funded innovations of the simultaneous ball milling/enzyme hydrolysis process will help compress the current 8-step biomass-to-fuel process into only 4 steps. This will produce critical operational and energy cost reductions needed for commercial production,” Kozak added.

-----

BETO supports technology research, development, and demonstration to accelerate greenhouse gas emissions reductions through the cost-effective and sustainable use of biomass and waste feedstocks across the U.S. economy. BETO is part of DOE's Office of Energy Efficiency & Renewable Energy.

Atlantic Biomass, LLC, a small business located in Frederick, Maryland is focused on the development and commercialization of proprietary enzymatic-based biomass “deconstruction” processes. These processes allow the use of low-cost, non-food biomass as feedstocks for renewable sustainable biofuels and bioproducts. Processes developed convert hemp biomass, sugar beet pulp and grasses into the building blocks for biofuels and other bioproducts, as well as dandelions for rubber.

The Maryland Energy Innovation Institute's mission is to catalyze clean energy technology to address climate change, stimulate economic growth, and create a sustainable future.

Published July 22, 2024