News Story

Electrified Plastic Recycling Toward A Sustainable Future

Multi-billion metric tons of plastic products exist worldwide, many of which become waste, and if not properly handled will cause severe damage to the environment. As the heavy demand for plastics continues, it is imperative to develop efficient recycling methods to ensure a sustainable future. Currently, much of this waste is burned or landfilled, which is extremely environmentally unfriendly and economically disastrous. To recycle and reuse plastics, mechanical processing has been somewhat effective in converting plastic wastes to low-end and low-quality products. Yet, the remolded materials often suffer from poor product value. Recent development in thermochemical processing allows the plastics to be converted to useful chemicals through reactions. However, conventional methods suffer from poor product selectivity and yield, limiting the practicality of this otherwise promising approach.

To circumvent these problems, a multi-institutional research team led by Liangbing Hu, Herbert Rabin Distinguished Professor from the Department of Materials Science and Engineering (MSE) at University of Maryland (UMD), and Director of the Center for Materials Innovation (CMI), invented an electrified technique to conduct thermochemical plastic recycling, which can be used to produce green, value-added chemicals such as monomers via the pyrolysis of polyolefin and polyester plastics. This study opens up a new route towards efficient thermochemical plastic recycling with renewable electricity. Dr. Qi Dong, an Assistant Research Scientist in the Hu group, served as the first author on the study published in Nature.

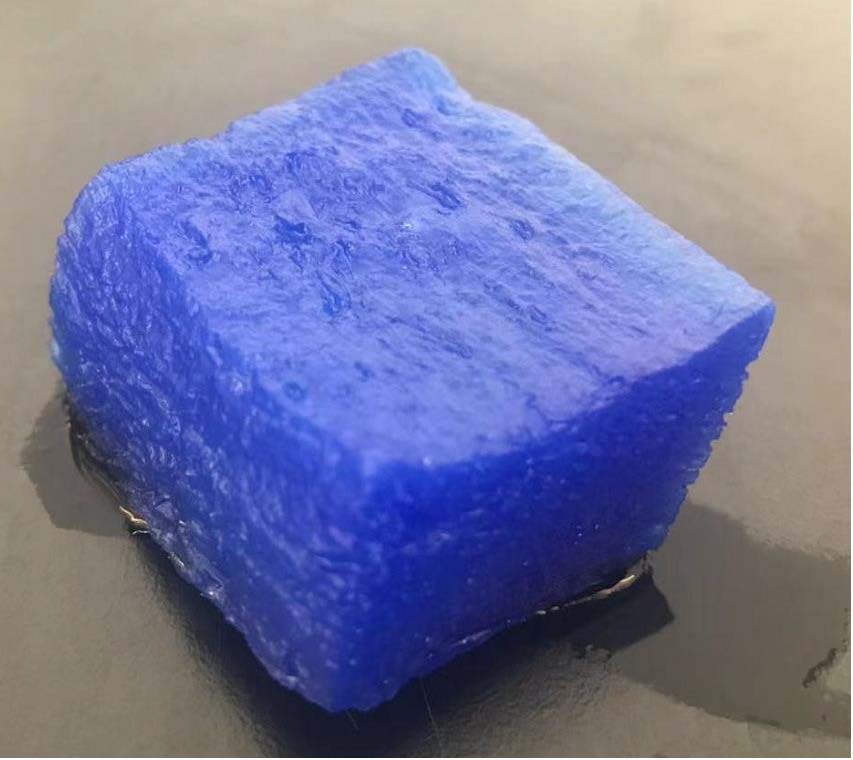

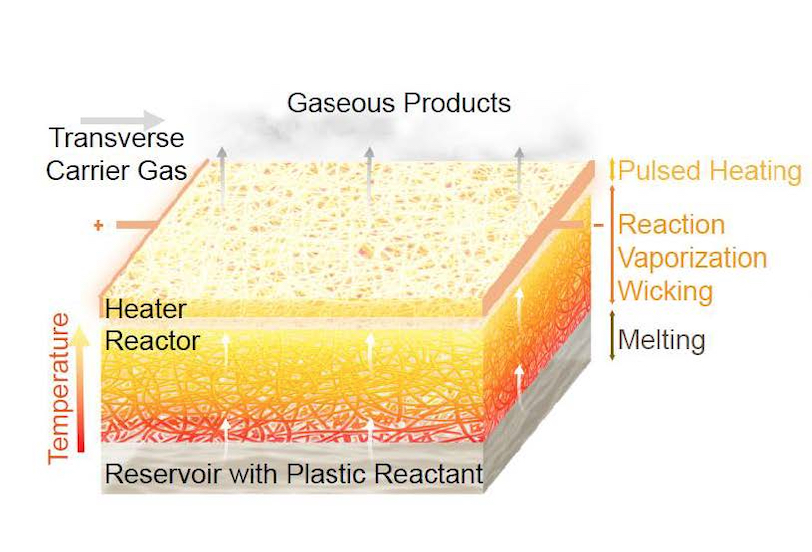

Our technique uses electrified heating within a bilayer porous reaction system to allow for both temporal and spatial control of the plastic pyrolysis process,” said Qi Dong. “Using this technique, we demonstrated converting polypropylene and polyethylene terephthalate, which are the materials often used to make plastic bottles and many commonly seen plastic products, to their constituent monomers with high yields.”

Not only does the technique show great performance in plastic recycling, it offers a unique far-from-equilibrium platform for chemical synthesis.

“This technique is unique in a way that it keeps the reaction of plastic pyrolysis in the far-from-equilibrium regime,” said Yiguang Ju, the Robert Porter Patterson Professor at Princeton University. “It can be extended to many other processes with unique product selectivity and reactivity by breaking the thermodynamic limit of reactions.”

Using this technique, electrified heating could enable green manufacturing of value-added chemicals from a range of plastic wastes and other feedstocks with renewable electricity.

This work stands out to me as a creative engineering approach to an otherwise frowned-on method of dealing with the burden of plastic waste: simply burning it. Limiting by-products and recapturing monomers from commodity plastics is not an outcome you would expect in an uncontrolled process, yet this is what the work achieves.

Claire Hansell, Senior Editor and Team Manager, Nature

“Our approach not only holds the potential to transform the global plastic life cycle, it can also be extended to upgrading a wide range of synthetic polymers and natural macromolecules for synthesizing value-added feedstock chemicals,” added Liangbing Hu. “In practice, our technique can potentially address some of the most pressing issues for plastic recycling and sustainable chemical synthesis.”

This is a multi-institutional study led by Liangbing Hu at the University of Maryland, Yiguang Ju at Princeton University, Dongxia Liu at the University of Delaware, Jianguo Mei at Purdue University, Xuejun Pan at the University of Wisconsin-Madison, and Ioannis Kevrekidis at Johns Hopkins University.

Professors Hu and Ju have formed a startup company, Polymer-X Inc., to commercialize the technology.

For additional information:

Dong, Q. et al (2023). “Depolymerization of plastics by means of electrified spatiotemporal heating,” Nature. DOI: 10.1038/s41586-023-05845-8

Published April 19, 2023